Did you know that lidding films play a pivotal role in extending the freshness of packaged food items?

Lidding films are flexible packaging materials that add an extra layer of protection to food in containers.

They are made from materials like paper, foils, polyethylene, and polyester, making them popular among food manufacturers, supermarkets, and food production companies.

In the domain of lidding films, options include peelable, lock-seal & resealable.

They are instrumental in preserving food freshness, preventing contamination, and extending the shelf life of various products like fresh produce, dairy, soups, meats, and microwave meals.

The following article will examine these films, from their usage to their particularities.

We’ll examine how they help keep our food safe and extend produce freshness.

What Are Lidding Films?

Lidding films represent a versatile category of packaging materials which provide an additional protective layer for products housed in rigid containers.

Crafted from various materials, these films cater to diverse packaging requirements.

Among their variations are peelable, lock-seal & resealable.

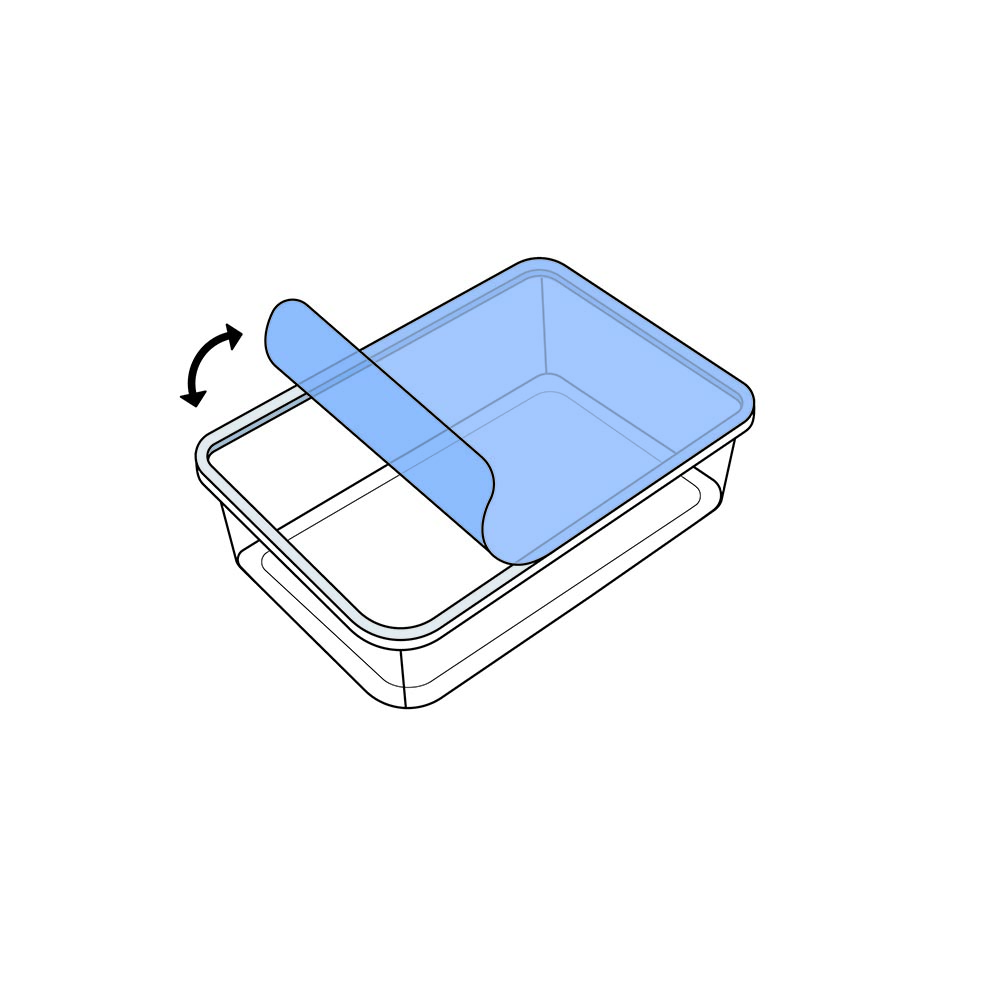

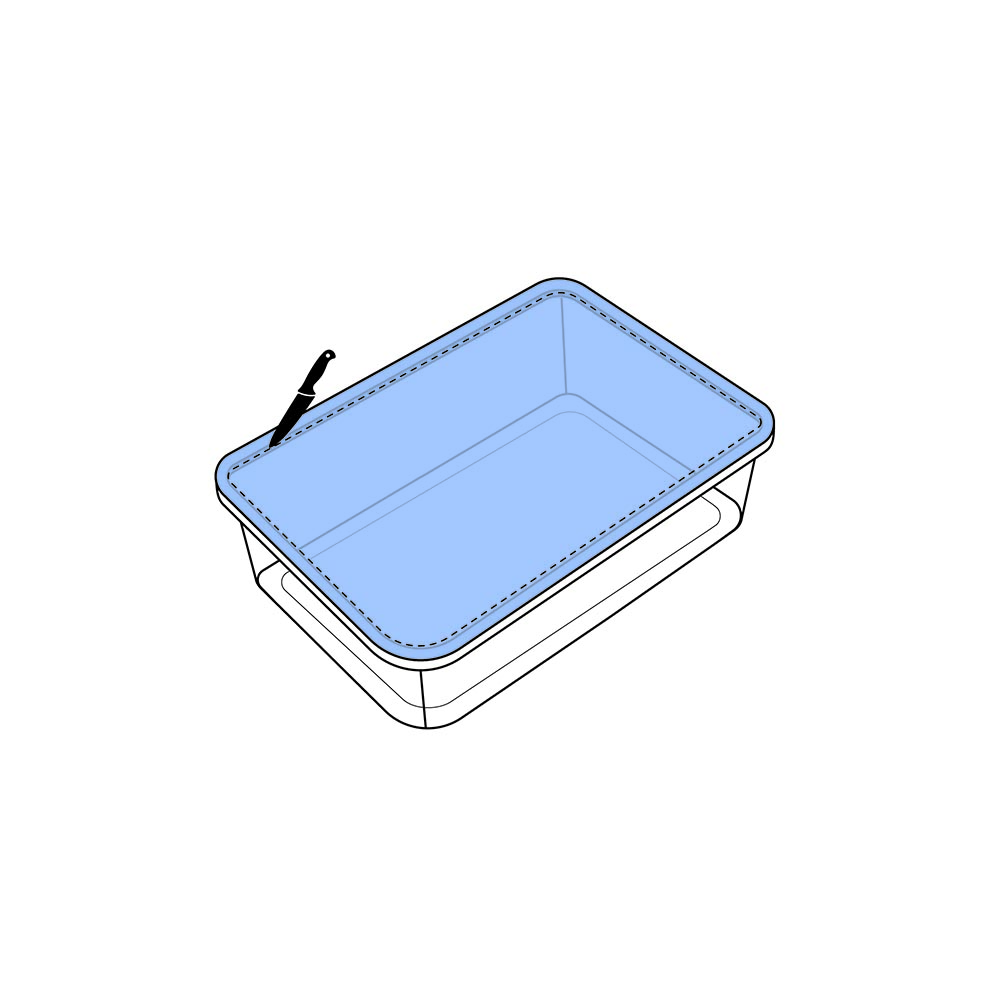

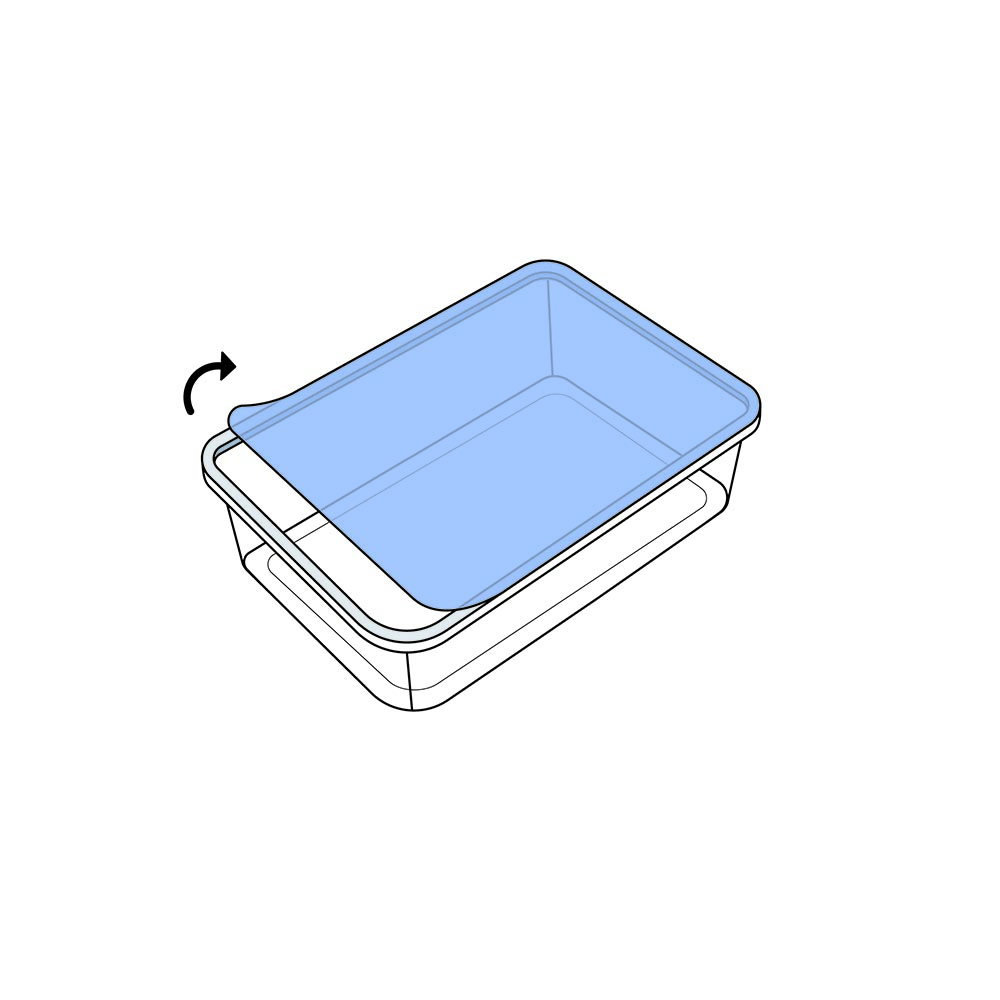

Easy-peel films facilitate effortless removal from containers, while lock-seal films establish a secure seal requiring a tool like a knife or scissor for opening.

Resealable lidding films allow consumers to open & reseal the package and maintain freshness over an extended period of time.

| Types of Lidding Films | Benefits | Additional Features |

| Easy-peel films | -Facilitates effortless removal from containers. -Provides easy access to products. | Anti-fog, Freezable High oxygen (perforated, micro, hot needle, 5mm) Printed Medium to high barrier Freezable, Self-venting, Ovenable |

| Lock-Seal films | – Requires tool (knife or scissor) for opening. -Ideal for product protection or tough handling. -Provides strong seal with tray. | Anti-fog, Freezable, Printed (perforated, micro, hot needle, 5mm), Medium to high barrier, Ovenable, Freezable |

| Resealable Films | -Allows consumers to open and reseal package. -Maintains freshness over time. | Anti-fog, Medium to high barrier, Freezable (perforated, micro, hot needle, 5mm), Printed, Freezable |

Benefits of Lidding Films

Primarily used in the food industry, these films adeptly seal containers, paperboard pints, or trays housing dairy products, soups, meats, and microwaveable dinners.

Available in various materials and sizes, they aptly address the following needs:

- Extended Shelf Life: Functions as barriers against moisture, oxygen, and spoilage factors, extending product shelf life.

- Seal Integrity: Withstands handling and transportation, reducing contamination and leakages.

- Consumer Convenience: Designed for easy opening, enhancing customer accessibility without tools.

- Transparency: Allows customers to see products without opening, aiding purchase decisions.

- Tamper Evidence: Provides tamper features for consumer confidence in product integrity.

- Versatile: Compatible with various packaging types like trays, cups, and bowls made of plastic, metal, or paperboard.

- Improved Food Safety: Acts as a barrier to contaminants, ensuring safe, high-quality products.

Ultraperf: Premium Lidding Films for Food Packaging Excellence

At Ultraperf, we know how important these films are for packaging food.

With more than 30 years of experience, we provide top-notch lidding films that meet the strict food industry standards.

Our films ensure food stays safe and fresh until you’re ready to eat it. Trust us to keep your food products safe and appealing to everyone.

Whether you need films that peel easily, lock seal or reseal, we have what you need.

Our films work great with plastic containers, APET, CPET, PETE, PP, PE, PP coated trays, ALU, PLA, Cardboard coated PP, PE, PET, pints, or trays.

Explore our products page and contact our team if you have any questions.

Who Uses Lidding Films?

Lidding films are popular among many in the food sector, like food makers, grocery stores, and food companies.

Food manufacturers use these films to seal trays and containers tightly. This is for products such as fresh produce, dairy, canned soups, meats, baked goods & ready meals.

Supermarkets use these films to package fresh and pre-cooked foods safely. These films ensure the food stays safe and prevent issues during moving and storage.

Food processors use these films to make their products last longer.

Additional Features

Lidding films can meet various packaging needs. These include:

| Additional Features to Lidding Film | Key Features | Applications |

| 1. Anti-fog | Prevents fogging on packaging | Clear plastic containers for produce, salads |

| 2. Freezable | Withstands low temperatures, suitable for freezing temperatures | Refrigerated products, frozen desserts |

| 3. Perforated | Allows oxygen exchange | Fresh produce (fruits, vegetables, herbs, fresh seafood) |

| 4. Printed | Printed up to 8 colors for merchandising purposes | Retail applications, informative messaging or meal kits |

| 5. Barrier | Barrier against oxygen & moisture | Frozen meats, frozen meals |

| 6. Ovenable | Heat-resistant for oven use | Prepared meals, bakery products |

| 7. Self-venting | Allows excess steam to escape | Microwavable meals, steamable vegetables |

Common Questions

Is Lidding Film Recyclable?

If monolayered PET or PET, yes, they are recyclable. But beyond the film’s constitution, an important missing point in the sustainability question is the lack of facilities and technologies available to recycle these materials.

We’re also seeing more and more news coverage encouraging people and companies to ditch plastic and opt for paper. but it’s not that simple.

Reconsidering Paper Bags: Unveiling Environmental Realities

Switching from plastic to paper bags might seem like a more environmentally friendly choice, but a closer examination of the data suggests otherwise.

Studies have found that paper bags involve substantially more water and energy consumption than plastic bags, adding to their environmental impact.

Furthermore, the production of paper bags generates almost four times more CO2 equivalents compared to plastic bags.

Additionally, paper bags require more energy throughout their lifecycle, including the intensive processes involved in manufacturing and recycling.

In Sri Lanka, research indicates that paper bags have a higher global warming potential than plastic due to the energy consumed during production.

This data challenges the notion that paper is a greener alternative to plastic, underscoring the complexity of making environmentally conscious packaging choices

How Thick is Lidding Film?

Lidding film thickness changes to meet different needs.

You can find films in many thicknesses. Thicker films are tougher, while thinner films tend to be more flexible and less costly.

Choosing the right thickness depends on your specific needs.

Contact our team for specialized assistance if you’re unsure about your required thickness.

Is Lidding Film Plastic?

Yes, these films are mainly made from plastics like polyethylene, cast polypropylene, and polyester. These plastics seal well and protect the items inside.

They’re very popular in the food sector for their strength and alignment with food and safety regulations.

What Are the Benefits of Using Lidding Film in Packaging?

Lidding film offers excellent sealing properties, ensuring product freshness and protection during storage and transportation.

What Are the Key Factors to Consider When Selecting Lidding Films?

When selecting lidding films, factors such as the product being packaged, handling, merchandising, material compatibility, barrier properties, seal strength, and printing capabilities are crucial for effectively meeting packaging needs.

Can Lidding Films Be Customized?

Yes, lidding films can be customized. Material composition, thickness, size, and printing options can be changed to suit various packaging formats and branding preferences.